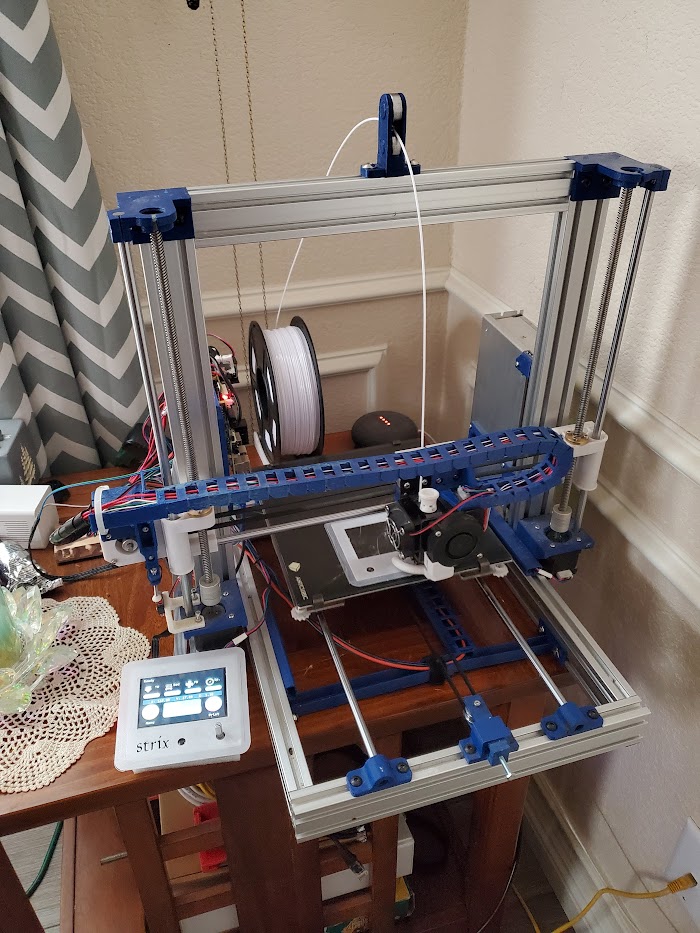

Dad’s first and only 3d printer. It all started as a budget Prusa clone and now there are very little left of its original parts. Aptly named strix later, if Dad started the hobby now, he would not start with an A8, but in his case, it’s more about the journey than the destination. Let’s dive into its evolution.

Modifications

Can’t talk about modifications without starting with what’s stock. It was pretty good from the start. Did not have any bells or whistles in features but once it’s set up, it printed pretty decently. Some of the first issues Dad wanted to address were fire hazards and reduce were frame vibration and bed adhesion issues. Here’s a list of current modifications Strix currently adorns (not in chronological order at all)

- AM8 parts

- SKR board mount

- BTT TFT35 mount

- X Belt Tensioner

- X Axis Cable Chain

- AM8 Y belt upgrade

- AM8 Underbed Cable Chain

- Z Adjustable Endstop

- Bigger Extruder Release Button

- Semi-Circular Fan Duct

- Bed Level Thumbwheels

- Spool Holder

Specifications

Build Volume: 220 x 220 x 240mm

Printer construction: Aluminum frame, glass plate with PEI coating

Nozzle diameter: 0.4mm

Print speed: 100mm/s

Material diameter: 1.75mm

Supporting materials: ABS, Luminescent, Nylon PVA, PLA, PP, Wood

x-axis, y-axis positioning accuracy: 0.012mm

z-axis positioning accuracy: 0.004mm

Hotend temperature: I’ve pushed it to 260°C

Heatbed temperature: ≤ 100°C

Components

Frame: 2040 aluminum extrusion to Anet A8’s dimensions

Mainboard: BIGTREETECH SKR 2

Display: BIGTREETECH TFT35 E3 V3.0.1

Extruder Hotend: Anet A8 Stock direct-drive

Stepper Drivers: BIGTREETECH TMC 2209

Stepper Motors: Anet 42SHDC3025-24B

Heatbed: Anycubic Ultrabase tempered glass plate

External mosfets installed for heaters

Octoprint image on a Rasp Pi 4 Model B 1GB